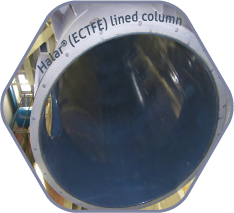

PVDF, ECTFE, ETFE and PFA Coatings

The application of fluorine-polymeric coating of thickness up to 1 mm is a protection technique alternative to heavier PTFE lining. The design of our equipment is made according to specific construction standards of each material. The metallic parts are designed and manufactured to obtain a uniform and precise coating.

Available materials:

- PVDF, Polyvinylidene fluoride, maximum operating temperature: 120°C.

- ECTFE, Ethylene / Monoclorotrifluoroetilene, maximum operating temperature: 150°C.

- ETFE, Copolymer Ethylene / Tetrafluoroethylene, maximum operating temperature: 150°C.

- PFA, Perfluoroalcoxy, maximum operating temperature up to 260°C.

These polymers are sprayed and baked in ovens, ensuring perfect adherence to the inner surface of metallic shell. The first layer is applied after the proper sandblasting procedure and it provides high adhesion of the coating, necessary to enable resistance to vacuum and high temperature. The next layers are intended to retard the permeation, along the multilayer structure.

The main characteristics of the fluorine-polymer coating are:

- Excellent resistance to corrosion (Ecarb assist the choice of suitable coating, depending on the process media).

- Seamless coatings, which allow a limited number of flanged joint and they are applicable on complicated geometries.